Knowing the

properties of ferrite magnets

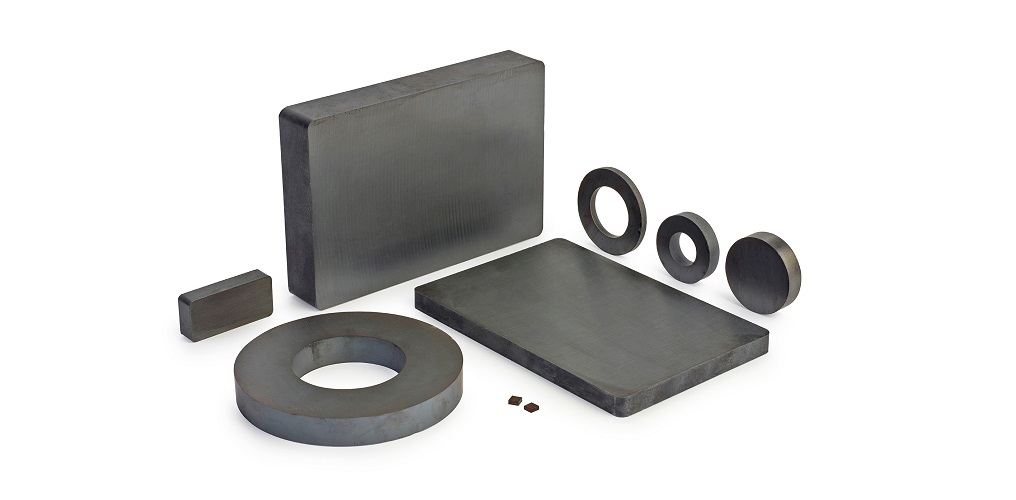

Ferrite Magnets and all their properties

Ferrite magnets are permanently attached and

have good mechanical properties that allow them to be cut into different shapes

and sizes. These magnets are cut with diamond tools, while standard drills and

wire spark erosion techniques do not work because they are electrically

insulating.

This occurs because the current does not pass

through them due to their extremely high electrical resistance, characteristic

from which they are known by their other name: ceramic magnets.

Ferrite magnets are manufactured by wet or dry

pressing and sometimes by extrusion. Wet pressing provides stronger magnetic

properties, e.g. C8 ferrite. Dry pressing provides better dimensional

tolerances, such as C5 ferrite.

In addition, the magnets are sintered to fuse

the powder and then processed to the final shape. The extrusion method can be

applied to produce arc segment shapes that are then cut lengthwise. Sometimes

new tools are required to produce ferrite magnets if existing tools do not

allow the desired shape to be produced. Typical tolerances for ferrite magnets

are +/- 0.25 mm, although +/- 3% is also used.

Improve heat resistance

When ferrite magnets heat up, their high

intrinsic coercivity really improves (improving demagnetization resistance)

making them extremely popular in motor and generator designs.

In fact, the use of ferrite magnets in

loudspeaker applications is very common, precisely because only these types of

permanent magnets become noticeably more resistant to demagnetization when

heated.

Ferrite magnets have a positive temperature coefficient

of intrinsic coercivity (it changes in +0.27% / degrees C with respect to the

environment) and only ferrite expresses this characteristic that much. However,

the magnetic output drops with temperature (it has a negative induction

temperature coefficient of -0.2% / ambient degC). The end result is that

ferrite magnets, or ceramic magnets, can be used at high temperatures with very

few problems.

Ferrite magnets can be used up to +250 degrees

C (and in some cases up to +300 degrees C), making them ideal for use in

electrical machines and most high temperature applications. At sub-zero

temperatures, for example, less than -10 to -20 degrees Celsius, ferrite

magnets may begin to show reduced tensile strength. That is, the temperature

and degree of attenuation depends on the shape of the magnet and are

application specific. In most applications, the operating temperature is not

low enough for this effect to occur.

This is because if its temperature coefficient

of +0.27% / degrees C of intrinsic Coercivity - the Hci drops as the magnet

cools. The ferrite can demagnetize if placed in a too cold environment, but it

is the total design of the magnetic circuit that determines how cold the magnet

must be before any impairement is noticed.

Characteristics and uses of ferrite magnets

Among the main features of ferrite magnets is the fact that it is possible to cut them without losing magnetism, while they can be used in a number of applications, including:

If you have doubts between buying a neodymium magnet or ferrite magnets, at IMA we help you choose the type of magnet that best suits your needs. If you have any questions, please ask us.